| WAGENER & POLASCHECK |

|

| Anlagentechnik für die Betonfertigteilindustrie |

| Gewerbestraße 5, D-33818 Leopoldshöhe, Tel. 05202 98200, Fax 05202 982022 |

|

|

| July 2011 |

| |

|

|

| |

The most efficient system using the wet cast or imme-diate formwork de-moulding method for the production of monolithic manhole bases with various channels and junctions. |

|

|

We are proud to present our new production system UNICO, using the wet cast or direct formwork de-moulding method for the production of monolithic manhole bases with various channels and junctions.

It consists of the milling centre for treating polystyrene blocks and the manhole con-figuration software.

|

|

| - 1 - |

|

|

| The components of the milling centre: |

| Colle Topmilling 120 |

| Milling centre for the production of channel negatives made of polystyrene for manhole bases with a nominal diameter 800, 1000 and 1200, junction negatives with a nominal diameter from 100 to 600, consisting of:

|

|

Milling tools

Control by CNC

CAD-CAM software also for the creation of three-dimensional drawings

Two vacuum clamping devices

Complete facing

Safety appliances according to CE safety regulations

|

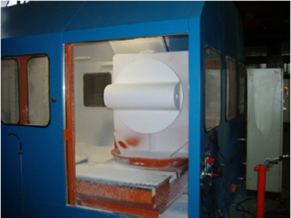

The Colle Topmilling is a five-axle column

milling-machine with a swivelling cross

table in front of it, which is furnished with

two vacuum clamping devices for various

dimensions. One of the clamping devices can be

swivelled.

|

|

|

The machine works fully automatically according

to the specifications of the operations scheduling.

The milling machine is equipped with a special

exhaust system and completely faced, which means

that the machine can be installed at any place.

|

|

|

|

| - 2 - |

|

|

|

|

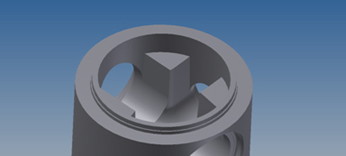

Manhole configuration software

for the creation of a manhole base according to the specifications given in the order. The software creates the respective three-dimensional drawing for the channels, the junctions and the complete manhole base.

|

|

|

|

Supplementary equipment for nominal diameter 1500

for the cutting a polystyrene channel negative with a nominal diameter of 1500 for the production of channel heights up to 1000 mm. |

Polystyrene exhaust system

for nearly complete extraction of milling chippings during the production process.

|

|

| - 3 - |

|

|

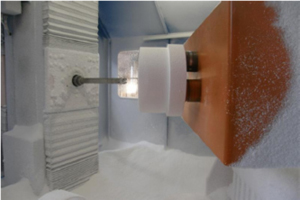

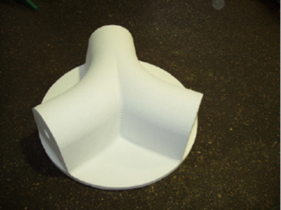

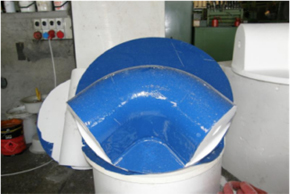

Wet cast method

The finished channel negative with fixed

junctions is inserted in a manhole

concreting machine and filled with

concrete. After the setting time the

manhole base is de-moulded, turned and

the negative model is removed, in order

to be used again as required.

|

|

|

|

Immediate formwork de-moulding system

The finished channel negative with fixed junctions is inserted in a partly or fully automatic manufacturing plant, filled and de-moulded directly by means of a special supporting system. Depending on the production methods the manhole bases are turned after the setting time and the negative models are taken off. They can be used again as required.

|

|

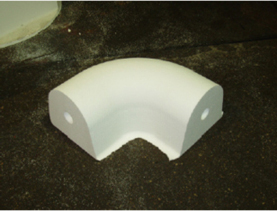

Channel forming

In this working step negatives with or without

berm can be manufactured. If requested,

faces and drillings in the junction zone can be

made immediately on the channel negative.

This makes the positioning of the junctions

easier and an inferior wall thickness is

possible.

|

|

|

|

|

|

|

| - 4 - |

|

|

|

Release film or release agent

We supply a special film to optimize the surface and facilitate the de-moulding of the negative models. After the production process the film can be removed and the negative model can be disposed of without pollutant. Depending on requirements a combination of release agent and release film can be used in order to obtain a certain surface texture.

|

|

|

|

|

| Innovative mounting and dismounting of manhole junctions |

|

| Special plug connections ensure exact and fast mounting and dismounting of the junction elements. |

|

Remove the polystyrene channel negative from the hardened manhole by means of a hook extractor. In this way it is possible to reuse the negative.

|

| - 5 - |

|

|

|

We hope to have succeeded in convincing you of the advantages offered by this innovative manufacturing system and are always at your disposal for any further questions in this re-

spect. We would be very pleased to receive your favourable response. |

|

| Further information can be obtained at: |

|

Wagener & Polascheck Vertriebs GmbH & Co. KG

Anlagentechnik für die Betonfertigteilindustrie

Gewerbestraße 5

D- 33818 Leopoldshöhe

|

|

Tel.: +49 05202 98200

Fax: +49 05202 982022

Email: info@wapo-team.de

Internet: www.wapo-team.de |

|

| Kind regards, |

|

Wagener & Polascheck

Anlagentechnik für die Betonfertigteilindustrie

(Installation engineering for the pre-cast concrete industry) |

|

Polascheck, Peter / Wagener, Jürgen

Managing Directors |

|

| - 6 - |

|

|